Footsteps echo on a half‑dry slab, and the smell of fresh cement hangs in the warm air.

A truck rolls up, but the mix inside does not bite the planet as hard as old‑style concrete once did.

Builders smile—less smoke in the sky, same strong floor beneath their boots.

Table of Contents

1. A Fresh Start on Site

2. Why Concrete Needs a Clean‑Up

3. New Mixes, Less Cement

4. Smart Trucks, Smart Timing

5. Waste Becomes Treasure

6. People Who Lead the Charge

7. How You Can Help

8. Looking Forward

1. A Fresh Start on Site

Walk past many worksites today and you will spot new colors on the mixer drums: bright green leaves, blue water drops, even tiny wind‑turbine logos.

These signs show a shift. Concrete suppliers now race to cut carbon and save raw stone. Their wins may look small at first, one load here, one load there, but the numbers add up fast.

2. Why Concrete Needs a Clean‑Up

Concrete builds roads, homes, tunnels, and dams. Yet the normal recipe uses a lot of cement, and making cement sends great clouds of carbon gas into the sky.

Some experts say cement alone makes about seven percent of all man‑made carbon gas. If builders want cooler summers and calmer storms, the gray mix in the drum must change.

3. New Mixes, Less Cement

Suppliers are swapping part of the cement for gentle helpers:

- Fly ash from power plants

- Slag from steel mills

- Calcined clay baked from common clay

- Recycled fine sand from old jobs

Each helper can cut carbon and save money too. A 2025 study on ash use showed a clear win: every ton of cement replaced with fly ash stops almost one ton of carbon gas from forming.

Low‑carbon mixes keep the same strength you count on. The trick is balance. Add too much helper, and early hardening slows down. Add too little, and carbon cuts fall short. Smart labs test blends every week, looking for the sweet spot.

4. Smart Trucks, Smart Timing

Wasted time burns fuel. Modern trucks use GPS and live traffic maps to find the fastest route. Plant panels show drum speed, mix warmth, and slump in real time, so drivers can fix problems on the fly. Less idle time, smooth roads, and on‑site pumps ready at the right minute mean fewer back‑and‑forth trips. That alone saves diesel and lowers dust around busy streets.

Some yards power their mixers with clean energy. Roof panels soak up sun by day and charge big batteries at night. A silent, electric drum at dawn does not wake the town, and no smoke drift marks the sky.

5. Waste Becomes Treasure

Old concrete rarely heads to landfills now. Large jaws crush chunks into sharp stones. A magnet pulls out rebar, which returns to the steel mill.

The crushed stone rides back to the batch plant to serve as fresh aggregate. Some firms even scrub and reuse gray wash water. This loop means less need to dig new pits, saving land and wildlife.

Cut pieces from precast jobs can also turn into giant Lego‑style blocks for earth walls. A simple coat of color turns them into street art, showing kids that reuse can be fun and strong at once.

6. People Who Lead the Charge

Big change starts with people—plant workers who tweak the mix, truck drivers who time each pour, and lab techs who keep careful notes. Owners reward bright ideas. One crew swapped paper tickets for phone apps that track loads. Another built a shade roof over the sand pile, so each batch starts with dry, light sand. Small moves like these lift both green goals and profit sheets.

Industry groups cheer them on with clear badges. Jobs that hit strict low‑carbon marks win gold stars in trade news and draw more work next season.

7. How You Can Help

Are you a home builder? Ask your supplier for a low‑carbon mix next time.

Are you an engineer? Add space in the plan for recycled stone.

Even buyers and city leaders play a part: choose bids that score high on carbon cuts, not just price.

Take note of size, slump, and cure time, then share results.

Each fresh data point helps labs sharpen the recipe and keeps costs down for the next crew.

8. Looking Forward

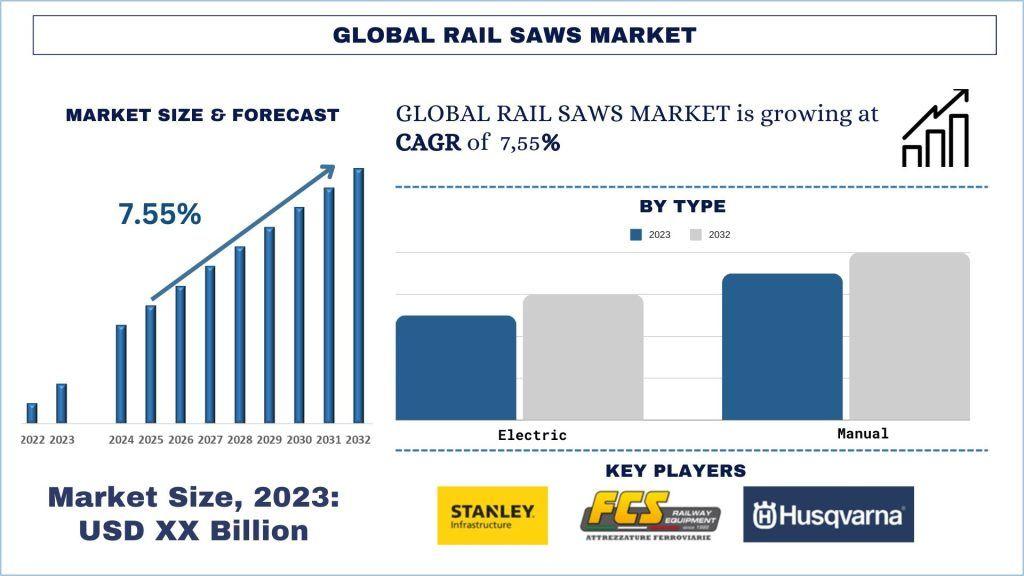

Market signs point upward. A 2024 study shows green concrete sales already near 34 billion US dollars, with a clear path to 69 billion US dollars by 2033.

That means smart money backs mixes that spare the air.

Over the coming years, carbon‑hungry cement plants will bolt on capture units.

Tiny gas bubbles will be pushed back into fresh slabs, locking carbon inside like fizz in a soda.

Robots will 3‑D print walls with zero waste, and drones will scan sites to give the batch plant the exact amount of mix it must send—no more, no less.

Step onto a site in ten years and the ground will still be hard, the beams still true, and the sky above a shade clearer. Concrete has not lost its place; it has found a cleaner story. And the hands steering the change belong to the quiet heroes driving the mixers today.