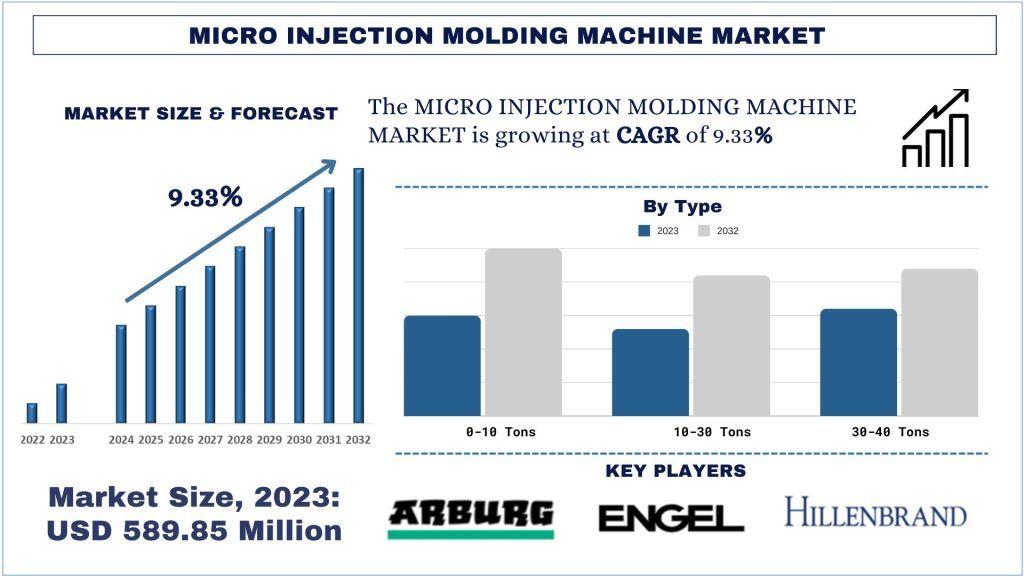

According to a new report by UnivDatos, the Micro Injection Molding Machine Market is expected to reach USD 1,232.51 million in 2032, growing at a CAGR of 9.33%.

The market is witnessing substantial growth driven by the increasing demand for precision and miniaturization in various industries, including medical, automotive, electronics, and consumer goods.

Demand:

The following drivers of growth in the micro injection molding machine market are that initially, there has been a new trend toward performing many operations using minimally invasive approaches, as well as a general increase in demand for small and complex medical parts and components. From the viewpoint of precision and efficiency, the medical industry has motivated the specifications of micro-injection molding machines for generating intricate constituent parts.

Also, the focus on lightweight and efficient vehicle components has equally fueled the market growth in the automotive industry. With the rising use of electric and self-driving cars, there is a demand for smaller and lightweight components that can only be produced through micro-injection molding. Likewise, the electronics industry has seen miniaturization over the years, particularly in wearable and portable electronics, thus creating high demand for these devices.

Applications:

The micro injection molding machine finds application in various industries and sectors, some of which are discussed below. The medical industry manufactures small and accurate parts with applications in such gadgets as catheters, implants, and surgical tools. Micro injection molding is widely used in the automotive industry to produce small but highly detailed components that can be used to optimize automotive performance and safety. The electronics industry has followed the miniaturization trend, and as a result, micro-injection molding machines that are used to produce small parts with intricate structures are in high demand. Machines with capacities between 10 to 30 tons are ideal for this task as they offer the level of accuracy necessary for electronic parts. For instance, in March 2023, Arburg introduced its automated micro injection molding cell, which integrated robotics alongside process control for increased accuracy and shorter cycle times. This innovation points to the direction in which the industry embraces mechanical and technological innovations.

In the consumer goods industry, micro injection molding is employed for making intricate and small parts such as gears of the watch and delicate operation parts in household appliances. These diverse applications have made micro injection molding machines vital in the production of small parts with high precision and accuracy.

Technological Advancements:

The technological growth of the market is relatively fast because key market proponents make massive investments in this regard. One significant development relevant to micro-IM is the combinability of automation and digitalization in micro injection molding. For instance, Arburg released, on March 15th, 2023, a new automated micro injection molding cell that includes robotic part handling and integrated process control, thereby improving the accuracy of installations and minimizing cycle intervals.

In addition, we have rapidly developed high-tech and new materials, enhancing new types of production technology. Engel Holding GmbH announced a new line of micro injection molding machines on February 10th, 2023, that featured enhanced alloys for longer lasting and high performance. Further, audited firms are practicing green manufacturing and environmental disclosures. For instance, in October 2022, Husky Injection Molding Systems established a reciprocal relationship with a sustainability-conscious organization to produce biodegradable micro-molded parts that would help in supporting the UN Sustainable Development Goals.

The manufacturer is also concerned with enhancing the models and their efficiency by increasing their accuracy and reliability. For instance, Wittmann Battenfeld provided details of a new micro injection molding machine that it planned to put into the market in August 2022. The machine was equipped with precise controls and energy efficiency to meet the new market requirement of high-precision micro-mold.

Access sample report (including graphs, charts, and figures) - https://univdatos.com/reports/micro-injection-molding-machine-market?popup=report-enquiry

Conclusion:

The global demand for micro injection molding machines is increasing due to the industries' shift towards precision and miniaturization. This report highlights that manufacturers are intensifying their efforts in innovation, driven by consumer needs, technological advancements, regulatory changes, and sustainability trends. With the growing emphasis on precision, miniaturization, and environmentally friendly practices, the micro injection molding machine market is poised for significant transformation and growth in the coming years as companies strive to develop cutting-edge and sustainable solutions to capture market share.

Key Offerings of the Report

Market Size, Trends, & Forecast by Revenue | 2024−2032.

Market Dynamics – Leading Trends, Growth Drivers, Restraints, and Investment Opportunities

Market Segmentation – A detailed analysis by Type and by Application.

Competitive Landscape – Top Key Vendors and Other Prominent Vendors

Contact Us:

Email - contact@univdatos.com

Website - www.univdatos.com