Market Overview

The global aluminum extrusion market was valued at USD 97.4 Billion in 2024 and is forecasted to reach USD 185.2 Billion by 2033, growing at a CAGR of 7.4% during the 2025-2033 period. The market is propelled by rising demands in the automotive, construction, and aerospace sectors, technological advancements in extrusion processes, and government initiatives focused on energy conservation. Asia-Pacific leads the market with a significant share due to low manufacturing costs and high demand across industries.

Study Assumption Years

- Base Year: 2024

- Historical Year/Period: 2019-2024

- Forecast Year/Period: 2025-2033

Aluminum Extrusion Market Key Takeaways

- The global aluminum extrusion market size was valued at USD 97.4 Billion in 2024.

- The market is projected to grow at a CAGR of 7.4% during 2025-2033.

- The market is expected to reach USD 185.2 Billion by 2033.

- Asia-Pacific dominated the market with over 74.0% share in 2024, driven by robust industrial growth and urbanization.

- The automotive industry’s shift to lightweight, fuel-efficient vehicles boosts demand.

- Construction sector expansion amid urbanization fuels product consumption.

- Technological advancements in extrusion and Industry 4.0 practices enhance product customization and output.

Sample Request Link: https://www.imarcgroup.com/aluminium-extrusion-market/requestsample

Market Growth Factors

Automotive and transportation is a major application. As demand for lightweight structures to improve fuel economy grows, aluminum extrusions have become an important tool in reducing vehicle weight to improve fuel economy and reduce greenhouse gas emissions. Global sales of EVs were forecasted to be about 17 million in 2024, or over one in five cars sold worldwide. Demand for aluminum extrusions in the EV market was expected to increase, mainly for battery enclosures and other structural components. Its corrosion resistance is useful for use on cars, boats, planes, and other structures, and investment in public transport.

The growing construction industry needed materials that had aesthetic appeal, high corrosion resistance and an excellent strength-to-weight ratio. The global buildings construction market size was USD 6.8 trillion in 2024, and the usage of aluminum extrusions in window frames, doors, roofs and other parts of buildings was steadily increasing. The primary marketplace drivers include green building certification, wherein recyclability of aluminum and aluminum extrusions is rated under LEED certification, rapid urbanization and growth of building construction in developing nations, as well as the expanding use of aluminum extrusion in building structures.

Direct, indirect and hydrostatic extrusion are used to manufacture complex aluminum profiles. Industry 4.0 technology such as real-time monitoring, predictive maintenance and data-based analytics increase the efficiency of the manufacturing process and improve product quality. The world smart manufacturing market size of USD 358.3 Billion in 2024 is an example of this, helping to reduce costs and increase production, competitive pricing, and product diversity. This means that industries that were previously not involving any aluminum extrusion due to costs or difficulty can begin the extrusion process.

Market Segmentation

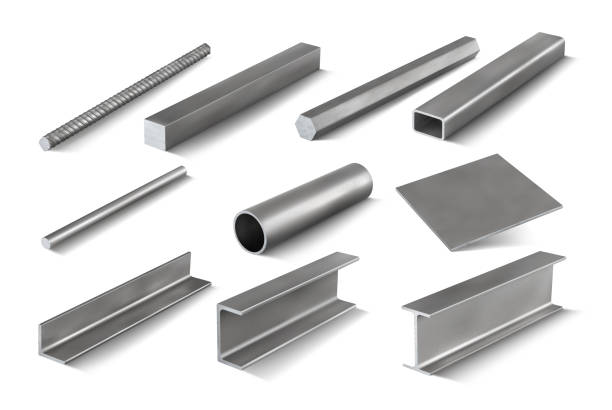

Analysis by Product Type:

- Mill Finished: Mill finished extrusions hold 57.6% market share in 2024. These aluminum profiles remain uncoated after extrusion, offering versatility, adaptability, and cost-efficiency. They allow easy customization for diverse applications such as construction, automotive, and electrical engineering, avoiding additional finishing time and cost while providing adequate corrosion resistance and strength.

Analysis by Alloy Type:

- 6000 Series Aluminum Alloy: Leading the alloy segment with 49.7% share in 2024, this alloy comprises aluminum, magnesium, and silicon. It is highly versatile with high strength, excellent corrosion resistance, and superior machinability, making it crucial in automotive and construction sectors for lightweight, durable parts like window frames and roofing systems.

Analysis by End-Use Industry:

- Building and Construction: Dominating with 61.4% market share in 2024, this sector values aluminum extrusions for flexibility, aesthetic appeal, and sustainability. Rapid urbanization and complex building designs that incorporate energy efficiency systems increase demand. The recyclability of aluminum contributes to green building certifications.

Regional Insights

Asia Pacific dominated the aluminum extrusion market in 2024 with a 74.0% share. Industrial growth and urbanization in countries like China, India, Japan, and South Korea drive high demand, especially in automotive and construction sectors. Regional government investment in infrastructure and expanding manufacturing capacity further reinforce Asia Pacific’s position as the global market leader.

Recent Developments & News

- June 2024: LoadLok introduced the IsoLok 3073 Alu RS Track, an aluminum extrusion track system enhancing payload and production efficiency for refrigerated trailers.

- February 2024: Atomic13 aims to commercialize ShAPE technology to recycle aluminum scrap into low-carbon extruded parts, targeting building industry applications and supporting energy efficiency and circularity.

- January 2024: Superior Extrusion Inc. expanded facilities in Gwinn, MI, installing a new 3,000-ton aluminum extrusion press, increasing capacity.

- January 2024: Jindal Aluminium launched a new fabrication division and an environment-friendly powder coating unit, enhancing its product offerings.

Key Players

- LoadLok

- Atomic13

- Superior Extrusion Incorporated

- Jindal Aluminium

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

Request For Customization: https://www.imarcgroup.com/request?type=report&id=1340&flag=E

About Us

IMARC Group is a global management consulting firm that helps the world’s most ambitious changemakers to create a lasting impact. The company provide a comprehensive suite of market entry and expansion services. IMARC offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us

IMARC Group,

134 N 4th St. Brooklyn, NY 11249, USA,

Email: sales@imarcgroup.com,

Tel No: (D) +91 120 433 0800,

United States: +1-201971-6302