The Pallet Stretch Wrapping Machine Market is witnessing substantial growth as industries worldwide prioritize efficient packaging, product safety, cost reduction, and logistics optimization. Stretch wrapping machines play a critical role in stabilizing palletized loads using stretch film, ensuring goods remain intact during transportation, storage, and distribution.

With the rapid expansion of e-commerce, food & beverage production, pharmaceuticals, manufacturing, and third-party logistics (3PL), demand for automated pallet wrapping solutions continues to accelerate. Companies are increasingly adopting high-speed, automated, and smart stretch wrapping systems to enhance productivity, minimize labor dependency, and improve load consistency.

This comprehensive analysis explores market size, growth drivers, segmentation, technological advancements, regional trends, competitive strategies, and long-term outlook.

Stay informed with our latest Pallet Stretch Wrapping Machine Market research covering strategies, innovations, and forecasts. Download full report:

https://www.databridgemarketresearch.com/reports/global-pallet-stretch-wrapping-machine-market

What is a Pallet Stretch Wrapping Machine?

A pallet stretch wrapping machine is industrial packaging equipment used to wrap stretch film around palletized goods. The purpose is to:

-

Secure products during transport

-

Prevent moisture and dust damage

-

Improve load stability

-

Reduce packaging costs

-

Enhance warehouse efficiency

Key Types of Pallet Stretch Wrapping Machines

-

Turntable Stretch Wrappers

-

Rotary Arm Stretch Wrappers

-

Orbital (Horizontal) Stretch Wrappers

-

Fully Automatic Stretch Wrapping Machines

-

Semi-Automatic Stretch Wrapping Machines

-

Mobile Stretch Wrapping Machines

Each machine type caters to different production volumes, load sizes, and operational requirements.

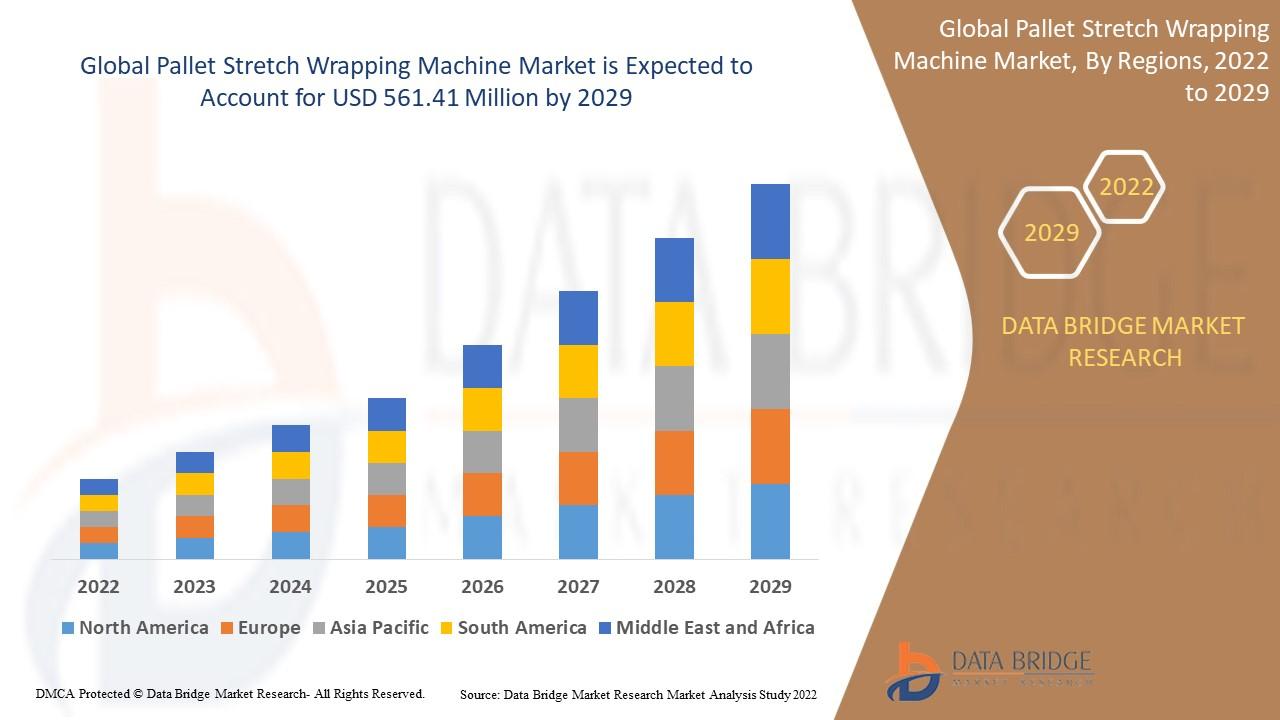

Market Size and Growth Outlook

The Pallet Stretch Wrapping Machine Market is projected to grow at a robust CAGR during the forecast period 2026–2033. Growth is fueled by:

-

Rising global trade and cross-border logistics

-

Expansion of warehouse automation

-

Increasing industrial production

-

Rapid growth of e-commerce fulfillment centers

-

Rising demand for load stability and packaging standardization

Emerging economies in Asia-Pacific and Latin America are particularly contributing to increased equipment installations due to industrial expansion and manufacturing growth.

Key Market Drivers

1. Rapid Expansion of E-Commerce and Logistics

The global boom in online retail has significantly increased demand for secure palletized shipments. Fulfillment centers require efficient, high-speed wrapping machines to handle growing order volumes.

2. Automation in Warehousing

Modern warehouses increasingly integrate pallet wrapping systems into automated conveyor lines and robotic palletizers. Fully automated stretch wrapping machines reduce labor costs and ensure uniform wrapping quality.

3. Focus on Cost Optimization

Stretch wrapping machines reduce film usage through pre-stretch technology, lowering material costs while maintaining load security.

4. Growing Food & Beverage Industry

Food and beverage manufacturers require hygienic, high-speed wrapping solutions to maintain product integrity during distribution.

5. Increasing Safety and Regulatory Standards

Industries such as pharmaceuticals and chemicals require secure palletization to comply with transport safety regulations.

Market Restraints

Despite strong growth, certain factors may limit expansion:

-

High initial investment for fully automated systems

-

Maintenance and operational costs

-

Price sensitivity in small and medium enterprises (SMEs)

-

Availability of low-cost manual alternatives in developing regions

However, long-term cost savings and efficiency gains typically outweigh upfront investment.

Technological Advancements Transforming the Market

1. Pre-Stretch Technology

Advanced pre-stretch film carriage systems stretch the film before application, reducing material consumption by up to 300%.

2. Smart Wrapping Machines with IoT Integration

Manufacturers now offer IoT-enabled machines capable of:

-

Real-time performance monitoring

-

Remote diagnostics

-

Predictive maintenance

-

Production data analytics

3. Energy-Efficient Systems

Modern machines consume less power while delivering higher output, aligning with sustainability goals.

4. Integration with Robotic Palletizers

Seamless integration into automated packaging lines enhances operational flow and minimizes manual handling.

Market Segmentation Analysis

By Machine Type

-

Turntable Stretch Wrappers

-

Rotary Arm Stretch Wrappers

-

Orbital Stretch Wrappers

-

Mobile Stretch Wrappers

Turntable machines dominate due to affordability and wide industrial applicability, while rotary arm systems are preferred for unstable or heavy loads.

By Automation Level

-

Manual

-

Semi-Automatic

-

Fully Automatic

Fully automatic systems are expected to witness the fastest growth due to Industry 4.0 adoption.

By End-Use Industry

-

Food & Beverage

-

Pharmaceuticals

-

Consumer Goods

-

Automotive

-

Chemicals

-

E-Commerce & Logistics

-

Manufacturing

The food & beverage segment accounts for a significant market share due to high palletized product volumes.

Regional Analysis

North America

North America holds a substantial share driven by:

-

Advanced warehouse automation

-

Mature logistics infrastructure

-

High labor costs encouraging automation

The United States remains the primary contributor in this region.

Europe

Europe demonstrates strong adoption of energy-efficient and sustainable packaging equipment. Stringent packaging and transportation regulations support advanced stretch wrapping technologies.

Asia-Pacific

Asia-Pacific is expected to record the highest growth rate due to:

-

Rapid industrialization

-

Growing manufacturing hubs

-

Expansion of export-driven economies

-

Rising e-commerce penetration

Countries such as China, India, Japan, and South Korea lead regional growth.

Latin America & Middle East

These regions show steady growth due to expanding logistics and industrial sectors.

Competitive Landscape

The Pallet Stretch Wrapping Machine Market is highly competitive with global and regional manufacturers focusing on:

-

Product innovation

-

Automation upgrades

-

Energy efficiency

-

After-sales service support

-

Customized solutions

Leading companies invest heavily in R&D to develop advanced high-speed and smart wrapping systems.

Strategic Initiatives Observed

-

Mergers and acquisitions

-

Expansion of manufacturing facilities

-

Strategic partnerships with logistics companies

-

Launch of compact and modular machines

-

Integration of AI-driven performance monitoring systems

Sustainability and Environmental Trends

Sustainability is becoming a critical factor in packaging equipment purchasing decisions.

Manufacturers are developing machines that:

-

Reduce film usage

-

Support recyclable and biodegradable stretch films

-

Lower energy consumption

-

Minimize packaging waste

The adoption of eco-friendly stretch films further enhances market attractiveness.

Emerging Opportunities

1. Growing Demand from SMEs

Affordable semi-automatic solutions create new opportunities in developing economies.

2. Custom-Built Systems for Heavy Industries

Heavy manufacturing sectors require specialized high-capacity wrapping systems.

3. Integration with Smart Factories

Industry 4.0 and smart manufacturing trends open new revenue streams for connected packaging solutions.

4. Growth in Cold Chain Logistics

Temperature-sensitive goods require secure pallet wrapping to maintain structural integrity during cold storage transport.

Future Market Outlook (2026–2033)

The Pallet Stretch Wrapping Machine Market is expected to maintain strong growth momentum due to:

-

Continuous automation trends

-

Rising global trade volumes

-

Expansion of warehouse infrastructure

-

Increasing focus on packaging optimization

-

Advancements in intelligent packaging machinery

Fully automated and robotic stretch wrapping systems are projected to dominate future demand. The integration of AI-driven analytics and predictive maintenance tools will reshape operational efficiency standards.

Why Businesses Are Investing in Advanced Pallet Stretch Wrapping Machines

Companies are prioritizing advanced machines because they deliver:

-

Faster wrapping cycles

-

Reduced film consumption

-

Lower labor costs

-

Enhanced product protection

-

Consistent wrapping quality

-

Improved workplace safety

As global supply chains become more complex, efficient pallet stabilization solutions are no longer optional—they are essential.

Conclusion

The Pallet Stretch Wrapping Machine Market stands at the forefront of industrial packaging automation. Driven by logistics expansion, manufacturing growth, cost optimization needs, and technological innovation, the market is poised for sustained long-term growth.

Browse More Reports:

Global Water Treatment Chemicals Market

Global Mobile Money Market

Global Sauces Market

Global Smart Fleet Management Market

Global Artificial Intelligence (AI) in Insurance Market

Global Scented Candle Market

Global Tote Bags Market

Global Tuna Market

Europe Japanese Restaurant Market

Global Dietary Supplements Market

Global Ceramics Market

Global Gemstones Market

Global Hepatocellular Carcinoma Drugs Market

Global Japanese Restaurant Market

Global Party Supplies Market

About Data Bridge Market Research:

An absolute way to forecast what the future holds is to comprehend the trend today!

Data Bridge Market Research set forth itself as an unconventional and neoteric market research and consulting firm with an unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process. Data Bridge is an aftermath of sheer wisdom and experience which was formulated and framed in the year 2015 in Pune.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Email:- corporatesales@databridgemarketresearch.com