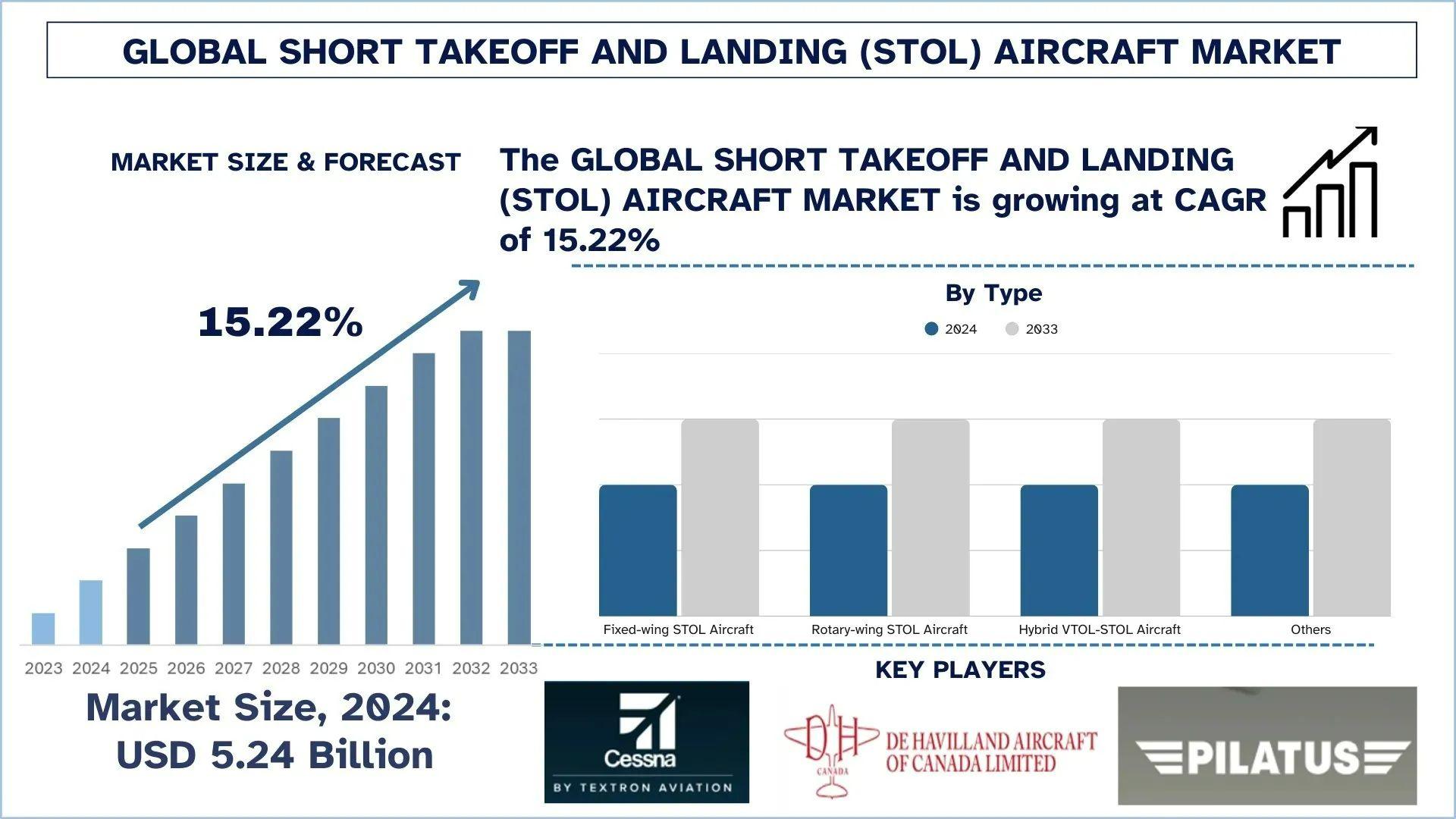

Modern manufacturing thrives on speed and precision. From my nearly two decades of work in designing customised ERPs, I know ERP is the backbone that connects smart machines, data analytics, and agile decision-making. With Output in the Manufacturing market is projected to amount to US$49.57tn in 2025, their is increasing demand for Manufacturing ERP that are customized as per industry - wise demand.

Our ERP solutions integrate seamlessly with IoT devices, AI-driven forecasting, and advanced automation systems to keep you ahead of industry demands.

As manufacturing goes online, everything is becoming more digital, from coming up with ideas for products to making them and sending them out.

With the help of technologies like the Internet of Things (IoT), smart factories, and Industry 4.0, companies are changing how they create, make, and ship their products.

For companies to stay competitive, they need systems that work together, can handle complexity, and give them actionable intelligence in real time.

The Digital Transformation of Manufacturing

The manufacturing industry is adopting new technologies that make automation, connectivity, and smart decision-making possible. IoT sensors gather information from machinery on the factory floor, and Industry 4.0 projects are aimed at combining cyber-physical systems.

Smart factories use this information to maximize production and minimize downtime. But processing this huge volume of data and aligning processes need an effective ERP system adapted to manufacturers' requirements.

Centralized Control Over Complex Processes

Successful production involves smooth alignment of numerous moving components, frequently across numerous locations and departments.

ERP systems supply a central control point at which combined data is available in real time, supporting rapid decision-making and improved transparency. In this regard, ERP for Manufacturing Industries assumes a pivotal position. By developing ERP systems personalised to manufacturing needs, developers make the software suitable for processing intricate production schedules, supply chain coordination, and quality control operations.

This tailoring enables businesses to manage multi-site manufacturing with ease while maintaining consistent standards and operational efficiency at every location.

Compliance, Safety, and Sustainability

Manufacturers are subject to strict regulatory requirements like ISO certifications, OSHA safety standards, and environmental rules of compliance. ERP systems assist in monitoring and documenting compliance activities comprehensively, minimising risk during audits and inspections.

Besides, contemporary ERP solutions also include sustainability metrics, enabling organizations to reduce waste and track resource consumption to achieve corporate social responsibility objectives.

Risk Reduction Through ERP

ERP systems improve risk management by providing real-time alerts that inform managers of impending problems before they worsen. With intrinsic data integrity tools and audit trails, ERP documents all activities, promoting traceability and accountability.

ERP as a Competitive Edge in 2025

In the future, ERP will remain an essential differentiator for manufacturers. It allows for quicker reaction to changes in the market through real-time visibility and greater operational responsiveness. Higher levels of customer satisfaction become achievable through improved order tracking, precision delivery estimates, and more effective communication.

Conclusion

In today's quick-changing manufacturing landscape, ERP is no longer an extravagance or an afterthought. It is the cornerstone upon which manufacturers construct insightful, streamlined, and robust operations. Investing in custom manufacturing ERP development will keep your business competitive, compliant, and future-ready.