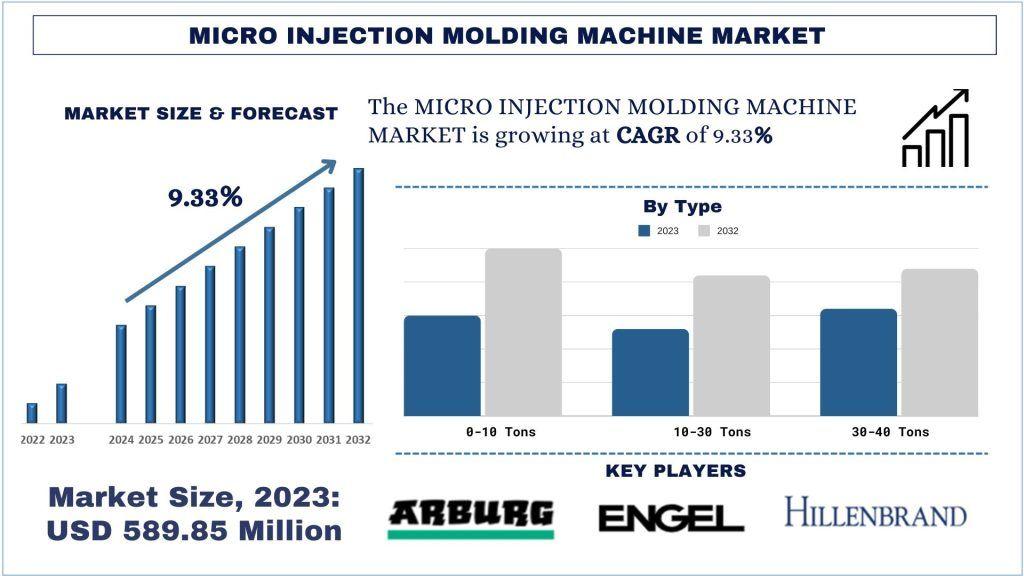

ARBURG GmbH + Co KG, a renowned name in the injection molding industry, has been at the forefront of driving innovation and excellence in micro injection molding technology. With a strong commitment to sustainability, cutting-edge research and development, and advanced manufacturing practices, ARBURG continues to deliver high-performance micro-injection molding solutions that cater to the evolving demands of various industries. According to a recent industry report by UnivDatos, The Global Micro Injection Molding Machines Market is projected to reach USD 1,232.52 million by 2032, growing at a CAGR of 9.33% from 2024 to 2032.

EMBRACING PRECISION AND MINIATURIZATION TRENDS

ARBURG offers a comprehensive portfolio of micro injection molding machines designed to meet the stringent requirements of medical, automotive, electronics, and consumer goods industries. These machines are meticulously developed using advanced technologies and sustainable practices, ensuring superior performance, precision, and environmental responsibility.

ADVANCING MICRO INJECTION MOLDING TECHNOLOGY

Automated Micro Injection Molding Cells: In March 2023, ARBURG launched a new automated micro injection molding cell that combines robotic handling with real-time process monitoring. This innovative system enhances precision, reduces cycle times, and improves overall efficiency, catering to the growing demand for highly accurate and small components in various industries.

Energy-Efficient Solutions: ARBURG is committed to sustainability and reducing the environmental impact of its manufacturing processes. The company has introduced energy-efficient micro-injection molding machines with advanced precision controls and reduced energy consumption. These machines enhance production efficiency and support the industry's move towards greener manufacturing practices.

Access sample report (including graphs, charts, and figures)-https://univdatos.com/reports/micro-injection-molding-machine-market?popup=report-enquiry

Advanced Material Capabilities: ARBURG continues to innovate in materials, offering micro-injection molding machines that can handle specialized alloys and advanced materials. These capabilities ensure that ARBURG's machines can produce durable and high-performance components for applications in demanding industries such as automotive and medical.

SUSTAINABLE MANUFACTURING AND REGULATORY COMPLIANCE

Sustainable Practices: ARBURG is dedicated to implementing sustainable practices across its manufacturing processes. The company's micro injection molding machines are designed to minimize waste, reduce energy consumption, and utilize environmentally friendly materials. These efforts align with global sustainability goals and regulatory requirements, ensuring ARBURG remains at the forefront of eco-friendly manufacturing.

Collaborative Partnerships: ARBURG collaborates with customers, industry partners, and research organizations to drive innovation and sustainability in micro injection molding. These partnerships enable ARBURG to leverage a wealth of knowledge and expertise, developing advanced solutions that meet the evolving needs of its customers and the market.

Regulatory Compliance: ARBURG ensures its products adhere to the latest regulatory standards, providing customers with micro-injection molding machines that meet stringent safety and environmental guidelines. This commitment to compliance underscores ARBURG's dedication to quality and reliability.

CONCLUSION

ARBURG GmbH + Co KG keeps the passion for innovations and sustainability all over the company and a particularly emphasized cooperation orientation regarding the context of the microinjection molding segment. Currently, ARBURG continuously sets higher goals for itself in sales growth and profitability while continuously providing exemplary service to its clients and contributing significantly to the development of the microinjection molding technology industry. They ensure that aspects of a product like preciseness, miniaturization, or sustainability are demanded non-stop and align with that mission. As a critical player in the industry, ARBURG is well-positioned to capitalize on these opportunities and drive innovation and growth in the global micro injection molding machine market.

Contact Us:

Email - contact@univdatos.com

Website - www.univdatos.com