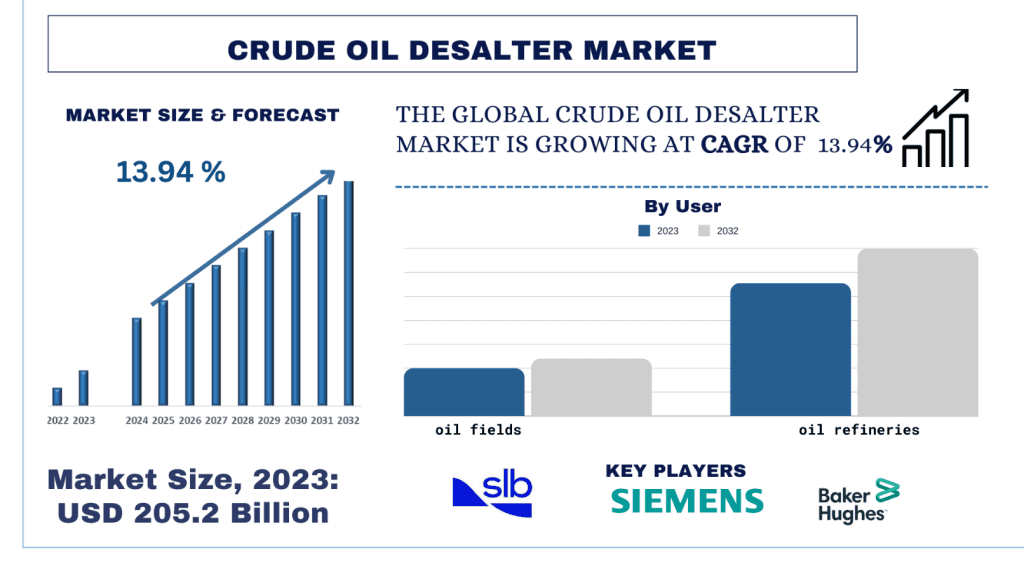

The Crude Oil Desalter Market was valued at USD 205.4 Billion in 2023 and is expected to grow at a strong CAGR of around 13.94 % during the forecast period (2024-2032).

Crude oil, the lifeblood of our industrialized world, needs a clean bill of health before it reaches the refinery. Desalting is a crucial process that removes water, salts, and other impurities that can wreak havoc on downstream equipment. However, the desalting market is not stagnant. Technological advancements are continuously improving efficiency, boosting capacity, and driving growth.

The Impurities that Lurk Within

Raw crude oil is far from the uniform black liquid at gas stations. It is a complex mixture containing water, salts, and other contaminants. These impurities pose significant challenges during refining:

Corrosion: Salts can form acids when heated, leading to the corrosion of pipes and equipment.

Fouling: Salt deposits can clog heat exchangers and distillation towers, hindering smooth operation.

Reduced Efficiency: Excess water content lowers the energy efficiency of the refining process.

Desalting tackles these issues head-on, ensuring cleaner and more manageable crude oil for refineries.

Tech Driving the Desalting Boom

The desalting market is projected to reach a value of over USD 205 billion by 2036, with a healthy Compound Annual Growth Rate (CAGR) of 13.94%. This growth can be attributed to several technological advancements:

Multi-stage Desalting: Traditional single-stage desalting might not be enough for heavy crude oil with high water and salt content. Two-stage and even three-stage desalting units are becoming increasingly popular. These systems provide a more thorough cleaning process, ensuring optimal results.

Recent Development (2023): GEA Group, a leading provider of refinery equipment, introduced a new design for a two-stage desalting unit that boasts superior efficiency and water removal capabilities.

Access sample report (including graphs, charts, and figures): https://univdatos.com/reports/crude-oil-desalter-market?popup=report-enquiry

Advanced Emulsion Breaking: Separating oil and water are a core function of desalting. New developments in emulsion-breaking chemicals and high-intensity mixing technologies are improving efficiency and reducing water content in the desalted oil.

Recent Development (2022): EcoEngineers, a specialist in oilfield chemicals, unveiled a novel emulsion breaker specifically formulated for heavy crudes. This innovation allows refineries to handle heavier feedstocks without compromising desalting performance.

Electrostatic Desalting: This technology utilizes high-voltage electrostatic fields to accelerate the separation of water droplets from the oil. Electrostatic desalting units are gaining traction due to their lower energy consumption and higher water removal efficiency than traditional methods.

Recent Development (2021): Schlumberger, a major oilfield services company, launched a new line of electrostatic desalting units designed for retrofitting into existing refineries. This advancement allows refineries to upgrade their desalting capabilities without significant downtime or capital expenditure.

Automation and Control Systems: Modern desalting units are increasingly equipped with sophisticated automation and control systems. These systems optimize operational parameters, such as demulsified dosage and water wash rates, improving efficiency and reducing operating costs.

Recent Development (2024): Yokogawa Electric Corporation, a leading industrial automation solutions provider, announced a new integrated control system specifically designed for desalting units. This system offers real-time process monitoring, data analysis, and predictive maintenance capabilities, ensuring smooth and efficient operation.

Click here to view the Report Description & TOC: https://univdatos.com/reports/crude-oil-desalter-market

The Regional Landscape: Where's the Boom Happening?

The growth of the desalting market isn't uniform across the globe. Here's a glimpse into the regional trends:

Asia Pacific: This region is expected to witness the most significant growth due to rising refinery investments, particularly in China and India. The increasing demand for heavier crudes also fuels the need for advanced desalting technologies.

North America: The US shale oil boom has led to a surge in demand for desalting units capable of handling high-water-content crudes. However, stricter environmental regulations might dampen growth in the future.

Europe: European refineries focus on modernization and efficiency upgrades, leading to a steady demand for advanced desalting technologies.

Looking Ahead: A Brighter, Saltier Future

Technological advancements are transforming the desalting market, making it more efficient, cost-effective, and adaptable to a wider range of crude oil feedstocks. As the industry strives for cleaner operations and handles heavier crudes, desalting will continue to play a vital role. Here are some exciting possibilities for the future:

Integration with Desulfurization: Combining desalting with desulfurization units could create a more streamlined process, reducing costs and footprint.

Advanced Materials: Developing new, corrosion-resistant materials for desalting equipment will enhance durability and operational lifespan.

Contact Us:

UnivDatos

Email: contact@univdatos.com

Contact no: +1 978 7330253

Website: www.univdatos.com

Linked In: https://www.linkedin.com/company/univ-datos/