In modern manufacturing, precision is everything. A single misalignment or loose connection can compromise an entire assembly, leading to wasted time, materials, and money. Enter the press fit tool — a specialized device designed to deliver exact, high-quality assembly with minimal effort. Whether you’re working in electronics, automotive production, or industrial machinery, understanding how a press fit tool works and why it matters can transform your workflow.

What Is a Press Fit Tool?

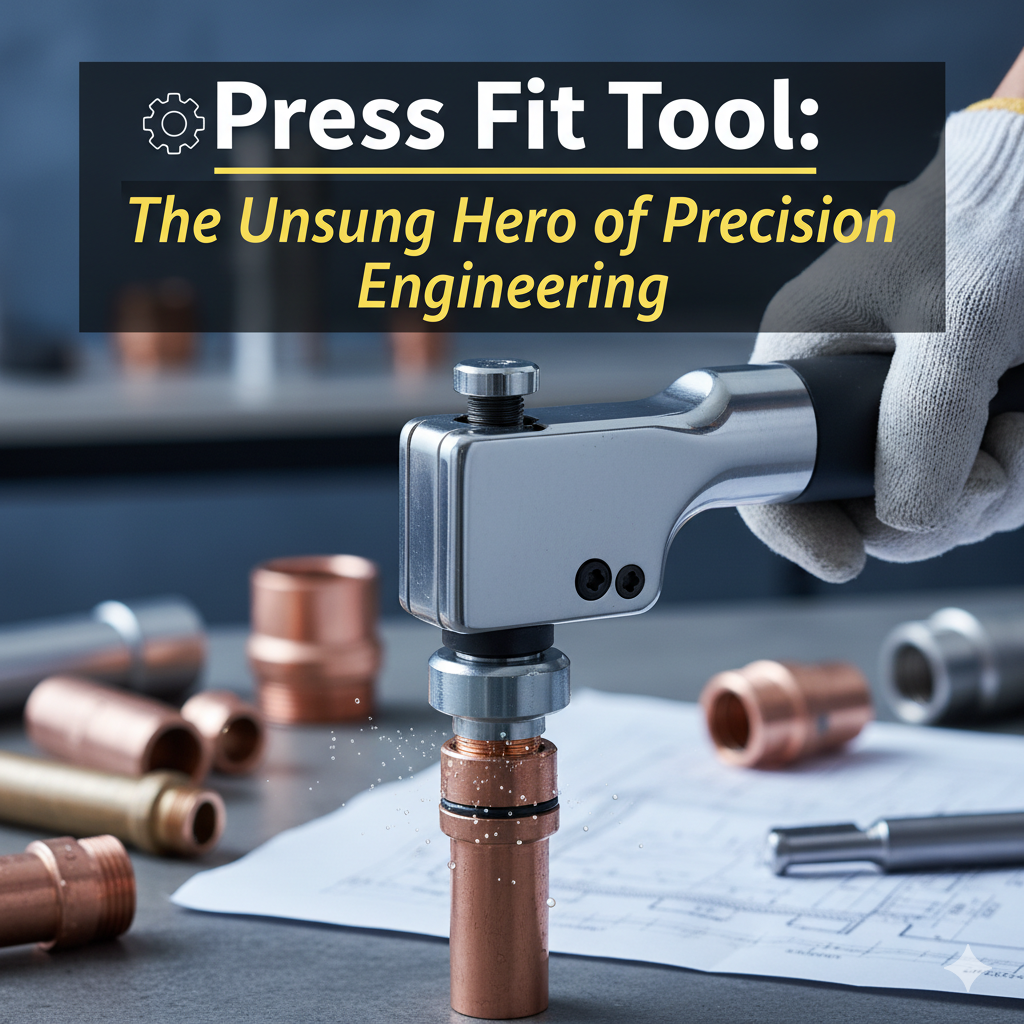

A press fit tool is a device used to assemble parts by pressing them together with controlled force, creating a secure, friction-based fit without the need for welding, adhesives, or fasteners. It is commonly used for inserting bearings, bushings, pins, and other components that require exact alignment.

Unlike traditional assembly methods, a press fit guarantees a tight connection that will not loosen over time, while also maintaining the integrity of the materials involved. This makes it essential in industries where both reliability and precision are non-negotiable.

How a Press Fit Tool Works

The concept of press fitting is simple: one component is slightly larger than the mating component’s opening. The press fit tool applies uniform force, pushing the parts together so that friction holds them securely. The process might seem straightforward, but achieving perfect alignment requires skill and the right tool.

Modern press fit tools come with:

-

Hydraulic or pneumatic systems: For smooth, controlled force.

-

Digital force monitoring: Ensures precise pressure application.

-

Adjustable heads or dies: To accommodate different part sizes.

-

Ergonomic design: Reduces operator fatigue during repeated use.

The result is a connection that is consistent, durable, and repeatable — crucial for large-scale production.

Applications of Press Fit Tools

1. Automotive Industry

Cars are built with thousands of small, interlocking parts. Press fit tools are used to insert bearings into wheel hubs, gears into transmissions, and bushings into suspension assemblies. These components must withstand vibration and stress, making precision essential.

2. Electronics Manufacturing

Printed circuit boards (PCBs) often require pins and connectors to be press-fitted. Using a press fit tool prevents damage to delicate electronic components, reduces assembly errors, and ensures electrical reliability.

3. Industrial Machinery

Heavy machinery uses press-fitted shafts, couplings, and rollers. A press fit tool allows engineers to assemble these components quickly and accurately, reducing downtime and maintenance costs.

4. Aerospace and Aviation

In aerospace, tolerances are extremely tight. Bearings, bushings, and fasteners must be inserted with exact pressure to ensure safety and performance. Press fit tools provide the reliability necessary for these high-stakes applications.

Advantages of Using a Press Fit Tool

-

Precision

Every component is aligned correctly, reducing the risk of misalignment and operational failure. -

Consistency

Automation and hydraulic systems allow for repeated, identical results, essential for mass production. -

Time Efficiency

Manual insertion of press fit parts can be slow and error-prone. A press fit tool speeds up assembly without sacrificing accuracy. -

Material Integrity

Unlike welding or adhesives, press fitting does not involve heat or chemicals, preserving the material’s original properties. -

Cost Savings

Fewer defects, less rework, and reduced downtime mean significant savings over time.

Choosing the Right Press Fit Tool

Selecting the right press fit tool depends on several factors:

-

Component Size: Ensure the tool can handle the diameter and length of the parts.

-

Required Force: Determine whether manual, hydraulic, or pneumatic operation is needed.

-

Precision Requirements: Digital or mechanical force control may be necessary for high-tolerance assemblies.

-

Operator Comfort: Ergonomics matter, especially in repeated assembly tasks.

-

Versatility: Some tools offer interchangeable dies or adjustable pressure for multiple applications.

Tips for Effective Press Fitting

-

Clean Components Thoroughly: Dirt or debris can affect the fit and damage components.

-

Lubricate If Recommended: Some assemblies benefit from light lubrication to reduce insertion force.

-

Align Parts Carefully: Misalignment can cause uneven stress or damage.

-

Monitor Force: Use digital gauges or built-in monitors to apply correct pressure.

-

Maintain the Tool: Regular maintenance ensures the press fit tool operates accurately over time.

The Future of Press Fit Tools

With Industry 4.0 and smart manufacturing on the rise, press fit tools are becoming smarter and more connected. Modern models feature:

-

IoT integration for real-time monitoring.

-

Automated force adjustment based on component material.

-

Enhanced safety features for operator protection.

This evolution ensures that manufacturers can produce high-quality assemblies faster, safer, and with unprecedented consistency.

Final Thoughts

A press tool is far more than a simple assembly device; it’s a cornerstone of precision manufacturing. From electronics to aerospace, the ability to create secure, consistent, and accurate fits impacts product quality, efficiency, and reliability. Investing in the right press fit tool isn’t just about machinery — it’s about building trust in every part, every assembly, and every product that leaves your facility.

For More Blogs: Click Here