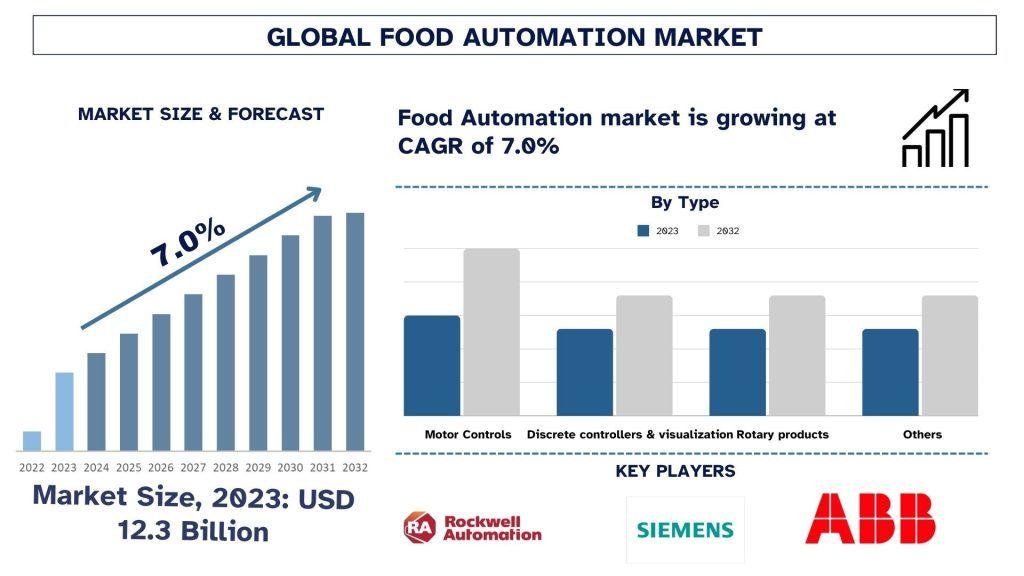

According to UnivDatos, the Food Automation Market was valued at approximately USD 12.3 Billion in 2023 and is expected to grow at a robust CAGR of around 7.0% during the forecast period (2024-2032).

Automation is rapidly reshaping the global food and beverage industry, driving major gains in operational efficiency, product consistency, and labor optimization. As manufacturers face increasing pressure to boost throughput and maintain high quality standards, the adoption of robotics, AI, and machine learning has become essential for staying competitive.

According to the International Robotics Federation, nearly 1.3 million industrial robots were deployed worldwide between 2015 and 2018. Food manufacturers integrating robotics into their production lines reported up to a 25% increase in productivity, underscoring the significant impact of automation on plant performance.

At the same time, food processors increasingly demand flexible automation technologies that support frequent product variations without costly line changes. Data from the Association for Packaging and Processing Technologies (PMMI) shows that 33% of food processing facilities now rely on automation, while 94% of food packaging operations had already implemented robotics by 2018.

Labor Shortages Continue to Drive Automation Demand

Ongoing labor shortages remain one of the biggest catalysts for automation in food and beverage manufacturing. The Association of Labor Providers reported that 70% of companies faced shortages of low-skilled and unskilled workers in 2018—accelerating the shift toward automated systems.

Artificial intelligence is also playing a more prominent role across the sector. In 2018, 57% of 1,300 surveyed organizations said they had implemented AI technologies, with another 18% planning adoption in 2019. AI is projected to deliver USD 1.2 trillion in annual value, highlighting its immense potential to transform food processing, packaging, safety monitoring, and supply chain operations. By 2021, experts estimated that over 80% of customer interactions would be managed through AI-driven tools.

AI and Machine Learning Accelerate Growth in Food Automation

AI and machine learning are becoming core components of modern food automation systems. These technologies enable manufacturers to increase speed, improve traceability, enhance accuracy, and optimize decision-making. With AI investments rising nearly 300% in 2017 alone, the industry is experiencing a rapid transition toward smart factories and intelligent production systems.

Access sample report (including graphs, charts, and figures) - https://univdatos.com/reports/food-automation-market?popup=report-enquiry

Regional Outlook: Asia-Pacific Leads the Global Food Automation Market

The Asia-Pacific (APAC) region held the largest market share in 2020, supported by rising disposable incomes, increased demand for ready-to-eat foods, and strong adoption of advanced manufacturing technologies.

North America is projected to record a robust CAGR due to rapid technological innovation, early adoption of automation tools, and strong investments in smart manufacturing initiatives.

Contact Us:

Email - contact@univdatos.com

Website - www.univdatos.com