In industries where extreme temperatures are the norm rather than the exception, accurate flow measurement becomes a critical challenge that demands specialized solutions. From petrochemical refineries to power generation facilities, the need for reliable flow monitoring in high-temperature environments has driven significant technological advancement. A high temp flow meter represents one of the most crucial innovations in industrial instrumentation, enabling precise measurement capabilities in conditions that would quickly destroy conventional equipment. These sophisticated devices must withstand temperatures exceeding 450°F (232°C) while maintaining accuracy and reliability, making them indispensable tools in modern industrial operations.

Understanding the Need for High-Temperature Flow Measurement

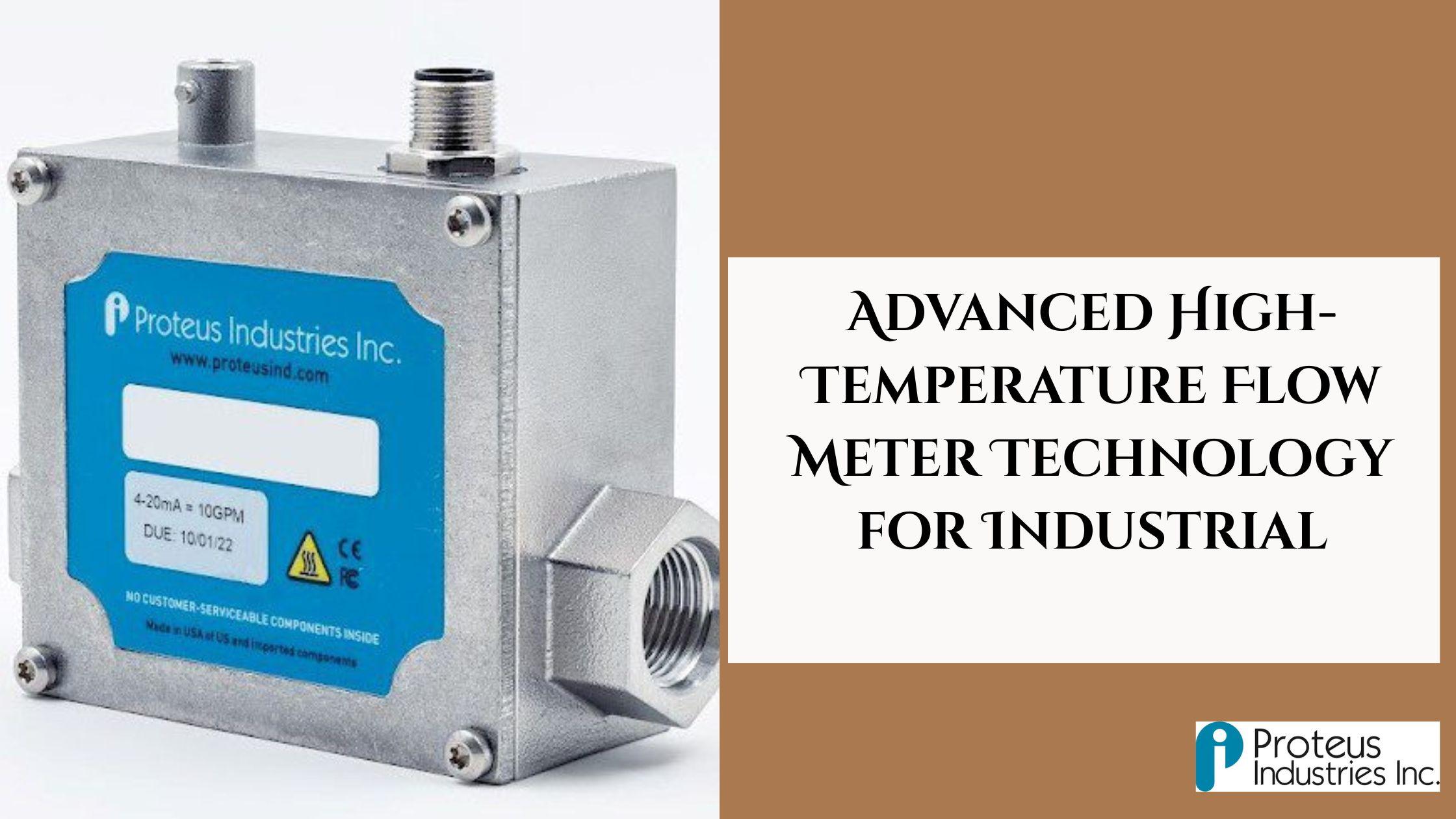

Industrial processes involving superheated steam, thermal oils, molten materials, and high-temperature gases require measurement solutions that can operate reliably under extreme thermal stress. Traditional flow meters often fail or provide inaccurate readings when exposed to elevated temperatures, leading to process inefficiencies, safety concerns, and costly downtime. The development of advanced high-temperature flow meter technology addresses these challenges by incorporating specialized materials, innovative design principles, and robust construction methods that ensure consistent performance even in the harshest environments.

Key Technologies in High-Temperature Flow Meters

Modern high-temperature flow meters employ several sophisticated technologies to achieve reliable operation:

- Vortex Shedding Technology: This method has emerged as particularly effective for high-temperature applications, utilizing the von Kármán vortex street, in which vortices are created as fluid passes around a bluff body. This principle remains consistent across wide temperature ranges, making it ideal for demanding environments. The sensors used in these devices must be carefully designed to maintain their piezoelectric or capacitive properties at elevated temperatures. Vortex flow meters offer excellent reliability with no moving parts, reducing maintenance requirements while providing accurate measurements for both liquids and gases.

- Thermal Mass Flow Meters: These devices measure flow by detecting heat dissipation from heated sensors, making them excellent for high-temperature gas flow applications. The technology relies on the principle that gas flowing past a heated element carries away heat proportional to the mass flow rate. While highly accurate for gas measurement, these instruments require careful calibration and temperature compensation to maintain precision across varying operating conditions.

- Differential Pressure Flow Meters: Traditional differential pressure technology, including orifice plates, venturi tubes, and flow nozzles, can be successfully adapted for high-temperature service through innovative design modifications. Remote seals and impulse lines protect sensitive pressure transmitters from direct heat exposure while maintaining measurement accuracy. This proven technology offers cost-effective solutions for many high-temperature applications, particularly in steam and hot gas systems.

- Ultrasonic Flow Meters: Advanced ultrasonic technology has been adapted for high-temperature use through specialized transducer designs and mounting configurations. These non-intrusive devices measure flow by analyzing the transit time of ultrasonic signals through the flowing medium. Clamp-on designs offer particular advantages in high-temperature applications by eliminating the need for process penetration, though careful acoustic coupling and temperature compensation are essential for accurate measurement.

Materials and Construction Considerations

The selection of materials for high-temperature flow meters is paramount to their success. Stainless steel alloys, particularly 316 and 316L grades, provide excellent corrosion resistance and maintain structural integrity at elevated temperatures. For even more demanding applications, exotic materials such as Hastelloy, Inconel, and titanium alloys offer superior performance. Ceramic components may be incorporated into sensor elements to withstand extreme thermal conditions while maintaining dimensional stability.

Gasket and seal materials present unique challenges in high-temperature applications. Traditional elastomers quickly degrade above 300°F, requiring the use of advanced materials such as graphite, PTFE with specialized fillers, or metal-to-metal seals. Proper thermal expansion management is critical and requires careful design to accommodate differential expansion rates among components without compromising measurement accuracy or causing mechanical failure.

Calibration and Accuracy in Extreme Conditions

Maintaining measurement accuracy across wide temperature ranges demands sophisticated calibration techniques and compensation algorithms. High-temperature flow meters must account for changes in fluid properties, dimensional variations due to thermal expansion, and shifts in sensor sensitivity. Modern devices incorporate advanced microprocessors that apply real-time corrections based on temperature inputs, ensuring consistent accuracy throughout their operating range.

Factory calibration procedures for these instruments often involve specialized facilities capable of replicating actual process conditions. Flow testing at elevated temperatures verifies performance under realistic operating scenarios, while thermal cycling tests ensure long-term stability. The calibration data is then programmed into the device's electronics, creating lookup tables or polynomial equations that enable accurate compensation during field operation.

Installation Best Practices

Proper installation is crucial for the optimal performance of high-temperature flow meters. Adequate straight pipe runs upstream and downstream of the meter prevent flow disturbances that could compromise accuracy. In high-temperature applications, thermal insulation must be carefully planned to protect personnel while ensuring the meter operates within its specified temperature range. Some installations require heat sinks or cooling systems to protect electronic components while allowing the sensing element to remain in direct contact with the hot process fluid.

Attention to piping stress is essential, as thermal expansion can impose significant forces on the flow meter body. Proper support and flexible connections help accommodate these stresses without affecting measurement performance. Additionally, the orientation of the meter may be critical for certain technologies, particularly those relying on gravity-influenced phenomena.

Applications Across Industries

High-temperature flow meters serve vital roles across numerous industrial sectors. In steam systems, they monitor superheated steam flow for power generation and process heating applications. The petrochemical industry relies on these devices for measuring hot hydrocarbons during refining and chemical processing. Thermal oil systems used for indirect heating applications require precise flow monitoring at temperatures often exceeding 600°F.

Metal processing operations utilize high-temperature flow meters to monitor cooling water systems, combustion air, and various process gases. The aerospace industry employs these instruments in engine testing and propulsion research. Even food processing facilities use them in cooking oil management systems and sterilization processes where accurate flow measurement at elevated temperatures ensures product quality and safety.

Future Developments and Innovations

The evolution of high-temperature flow meter technology continues with emerging developments in materials science, sensor design, and digital communication. Wireless sensing technologies promise to eliminate the need for complex wiring in hazardous high-temperature environments. Advanced diagnostics capabilities enable predictive maintenance by monitoring instrument health parameters and alerting operators to potential issues before failures occur.

Integration with Industrial Internet of Things platforms allows high-temperature flow meters to contribute real-time data to comprehensive process monitoring systems. Machine learning algorithms can analyze historical performance data to optimize calibration and accuracy improve over the device's lifetime. As industries push toward even higher operating temperatures and more aggressive process conditions, flow meter technology will continue advancing to meet these evolving demands, ensuring safe, efficient, and accurate flow measurement in the most challenging environments.

Conclusion

Advanced high-temperature flow meter technology represents a cornerstone of modern industrial process control, enabling safe and efficient operations in extreme thermal environments. Through continuous innovation in sensor design, materials engineering, and digital intelligence, these instruments deliver unprecedented reliability and accuracy. As industries demand ever-greater performance from their measurement systems, high-temperature flow meters will continue evolving to meet these challenges. Selecting the right technology, ensuring proper installation, and maintaining calibration integrity remain essential for maximizing operational efficiency, safety, and profitability in high-temperature applications across diverse industrial sectors worldwide.