In modern optical systems, precise light manipulation is crucial for devices like cameras, telescopes, lasers, and scientific instruments. Many manufacturers and engineers face challenges such as light dispersion, alignment issues, and reduced optical efficiency. A poorly selected optical element can cause image distortion, color inaccuracies, and measurement errors.

This is where a high-quality Prism becomes essential, ensuring precise light direction and optimal performance in a variety of optical applications.

Why Standard Optical Elements Fall Short

Not all glass or transparent materials can deliver the accuracy required for professional optics. Using substandard elements often leads to scattered light, unwanted reflection, and wavelength distortion.

Common Problems with Non-Precision Optics

-

Uneven light refraction causing blurred images

-

Color dispersion that affects imaging and measurements

-

Reduced brightness due to internal reflection losses

-

Misalignment affecting optical path accuracy

These challenges impact scientific research, imaging quality, and device reliability, making precise optical components critical.

How a Prism Solves Optical Challenges

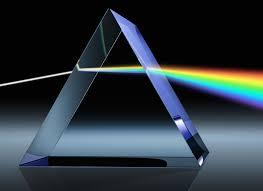

A prism is a solid transparent optical element with flat, polished surfaces designed to refract, disperse, or reflect light. By carefully controlling the geometry and material of a prism, engineers can manipulate light with high precision.

Key Advantages of Using Prisms

-

Accurate light bending and redirection

-

Controlled dispersion for spectral separation

-

Minimal internal reflection loss

-

Enhanced imaging and measurement accuracy

Using a Prism allows optical systems to maintain performance, clarity, and precision in even the most demanding applications.

Applications of Prisms in Optical Industry

Prisms are used extensively in devices that require precise light handling.

Major Use Cases

-

Cameras and binoculars for correct image orientation

-

Laser systems for beam splitting and alignment

-

Scientific instruments for spectroscopy and measurement

-

Optical communication systems for signal routing

-

Projectors and display systems for color separation

Each application relies on the prism’s ability to maintain optical accuracy and reduce distortion, making it indispensable in modern optics.

Optical Properties That Impact Performance

When selecting a prism, certain properties directly affect performance and output.

Critical Factors to Consider

-

Material refractive index

-

Surface flatness and polish quality

-

Dispersion characteristics for different wavelengths

-

Coating compatibility for anti-reflection or beam splitting

These factors ensure precise light paths, accurate color representation, and minimal energy loss.

Durability and Precision in Prism Manufacturing

High-quality prisms are designed to withstand environmental and mechanical stress while maintaining optical precision.

-

Temperature stability for high-power laser applications

-

Scratch-resistant surfaces for long-term use

-

Robust material for vibration and impact resistance

-

Consistent optical quality across batches

This ensures long-lasting performance and reliability for professional and industrial optical devices.

Conclusion

A prism is far more than a simple glass piece; it is a critical optical component that enables accurate light manipulation, reduces dispersion problems, and enhances system efficiency. Selecting the right prism ensures clear imaging, precise measurement, and optimal performance across applications ranging from scientific research to consumer optics.

For engineers and optical designers seeking reliable light control and minimal distortion, investing in precision prisms is a smart choice.