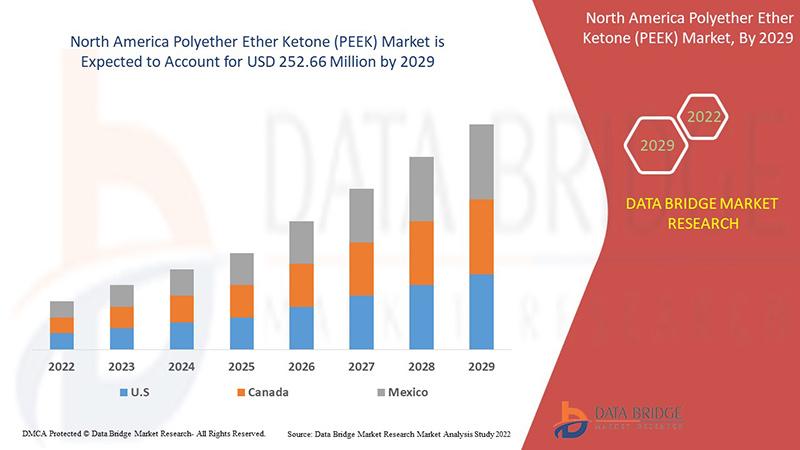

The North America Polyether Ether Ketone (PEEK) market is witnessing robust growth as industries increasingly demand high-performance materials capable of withstanding extreme temperatures, aggressive chemicals, mechanical stress, and stringent regulatory standards. PEEK, a semi-crystalline thermoplastic polymer belonging to the polyaryletherketone (PAEK) family, is widely recognized for its exceptional strength-to-weight ratio, thermal stability, electrical insulation properties, and biocompatibility.

In North America, especially in the United States and Canada, the adoption of PEEK is accelerating across high-value industries such as aerospace, medical devices, automotive, oil & gas, electronics, and industrial manufacturing. The material’s ability to replace metals in demanding applications—while reducing weight and improving performance—has made it a strategic material in advanced engineering and next-generation product development.

Uncover strategic insights and future opportunities in the North America Polyether Ether Ketone (PEEK) Market . Access the complete report:

https://www.databridgemarketresearch.com/reports/north-america-polyether-ether-ketone-peek-market

Overview of Polyether Ether Ketone (PEEK)

PEEK is known for its outstanding mechanical, chemical, and thermal characteristics, which include:

-

Continuous operating temperatures above 250°C

-

High tensile and flexural strength

-

Excellent wear and fatigue resistance

-

Superior chemical resistance to solvents, fuels, and acids

-

Low flammability and smoke emission

-

Outstanding electrical insulation

-

Proven biocompatibility for medical implants

These attributes position PEEK as a premium polymer for mission-critical applications where conventional plastics and even some metals fail to deliver long-term reliability.

North America Market Landscape

North America represents one of the most mature and technologically advanced markets for PEEK globally. The region benefits from:

-

A strong aerospace and defense manufacturing base

-

A well-established medical devices and healthcare ecosystem

-

High investments in R&D and materials science

-

Advanced automotive engineering and electrification trends

-

Stringent regulatory standards driving material innovation

The United States accounts for the majority of regional demand, followed by Canada and Mexico. Growth is supported by rising adoption of lightweight materials, increasing production of medical implants, and the shift toward high-performance polymers in industrial applications.

Key Market Drivers

1. Expanding Aerospace and Defense Applications

The aerospace and defense sector is one of the largest consumers of PEEK in North America. Aircraft manufacturers increasingly use PEEK for structural components, electrical connectors, cable insulation, bearings, and brackets due to its lightweight nature and high resistance to heat, radiation, and chemicals. The demand for fuel-efficient aircraft and advanced military systems continues to drive the use of high-performance thermoplastics.

2. Growing Medical and Healthcare Demand

PEEK is widely used in medical implants, spinal cages, orthopedic devices, dental implants, and surgical instruments. Its biocompatibility, radiolucency, and ability to be sterilized make it an ideal alternative to metals such as titanium. The aging population, rising incidence of orthopedic disorders, and increasing surgical procedures are fueling demand for medical-grade PEEK.

3. Automotive Lightweighting and Electrification

Automakers in North America are replacing metal parts with PEEK components to reduce vehicle weight, enhance fuel efficiency, and improve thermal and electrical performance. In electric vehicles (EVs), PEEK is used in battery systems, connectors, seals, and power electronics due to its heat resistance and electrical insulation properties.

4. Industrial and Energy Sector Adoption

The oil & gas, chemical processing, and power generation industries use PEEK for seals, valve components, compressor plates, and bearings. Its resistance to harsh chemicals, high pressures, and elevated temperatures makes it ideal for extreme industrial environments.

Market Segmentation

By Product Form

-

Unfilled PEEK

-

Carbon-filled PEEK

-

Glass-filled PEEK

-

Lubricated and reinforced PEEK

Carbon-filled and glass-filled grades are gaining popularity for applications requiring enhanced stiffness, wear resistance, and dimensional stability.

By Application

-

Aerospace and defense

-

Medical and healthcare

-

Automotive

-

Electrical and electronics

-

Oil & gas

-

Industrial machinery

-

Others

The medical and aerospace segments dominate the market due to high material value and specialized performance requirements.

By Processing Technology

-

Injection molding

-

Extrusion

-

Compression molding

-

3D printing

Additive manufacturing using PEEK is emerging rapidly, especially in customized medical implants and aerospace components.

Technological Advancements and Innovation

Innovation plays a crucial role in shaping the North America PEEK market. Leading manufacturers are focusing on:

-

High-purity and medical-grade PEEK for implantable devices

-

Enhanced flame-retardant and low-smoke formulations

-

Carbon-fiber-reinforced PEEK for ultra-high strength applications

-

PEEK filaments and powders for 3D printing

-

Cost-effective manufacturing processes

The increasing use of PEEK in additive manufacturing is a notable trend. 3D printing allows rapid prototyping, customization, and reduced material waste, which is particularly valuable in healthcare and aerospace industries.

Competitive Landscape

The North America PEEK market is moderately consolidated, with a few major players controlling a significant share. Key companies focus on capacity expansion, new product development, and strategic partnerships to strengthen their market position.

Major competitive strategies include:

-

Expanding production capabilities in the U.S.

-

Investing in R&D for specialty PEEK grades

-

Collaborating with medical device manufacturers

-

Developing sustainable and recyclable polymer solutions

-

Strengthening supply chains and distribution networks

Smaller regional players and specialty compounders also contribute to market growth by offering customized PEEK formulations for niche applications.

Regulatory Environment and Quality Standards

Strict regulatory requirements in North America significantly influence the PEEK market, particularly in medical, aerospace, and automotive applications. Manufacturers must comply with:

-

Medical device quality standards

-

Aerospace material certification requirements

-

Automotive performance and safety regulations

-

Environmental and workplace safety guidelines

These regulations, while increasing compliance costs, also promote the adoption of high-quality, high-performance materials such as PEEK.

Challenges and Market Restraints

Despite its advantages, the North America PEEK market faces several challenges:

High Material Cost

PEEK is significantly more expensive than conventional thermoplastics. Its high cost limits its adoption in price-sensitive applications and restricts its use to high-value sectors.

Complex Processing Requirements

Processing PEEK requires specialized equipment and high temperatures, increasing production complexity and manufacturing costs.

Limited Awareness in Emerging Applications

Some industries remain unaware of PEEK’s long-term performance benefits, leading to slower adoption in non-traditional applications.

Sustainability and Environmental Considerations

Sustainability is becoming increasingly important in the polymer industry. PEEK manufacturers are exploring:

-

Recycling and reprocessing technologies

-

Reduced-emission production methods

-

Bio-based or partially renewable feedstocks

-

Life-cycle analysis and carbon footprint reduction

Although PEEK is not biodegradable, its long service life and ability to replace metals contribute positively to overall sustainability goals.

Future Outlook of the North America PEEK Market

The future of the North America PEEK market appears highly promising. Market growth is expected to be driven by:

-

Continued expansion of aerospace and defense manufacturing

-

Rising demand for medical implants and surgical devices

-

Growth of electric vehicles and renewable energy systems

-

Increasing adoption of additive manufacturing

-

Advancements in high-performance polymer formulations

As industries continue to prioritize lightweighting, durability, and efficiency, PEEK will remain a material of choice for advanced engineering applications.

Conclusion

The North America Polyether Ether Ketone (PEEK) market is positioned for sustained growth, supported by strong demand from aerospace, medical, automotive, and industrial sectors. PEEK’s unmatched combination of thermal stability, mechanical strength, chemical resistance, and biocompatibility makes it a strategic material for high-performance applications.

Browse More Reports:

Global Water Treatment Chemicals Market

Global Scented Candle Market

Global Ceramics Market

Europe Japanese Restaurant Market

Global Smart Fleet Management Market

Global Tuna Market

Global Tote Bags Market

Global Gemstones Market

Global Japanese Restaurant Market

Global Hypochlorous Acid Market

Global Toothbrush Market

Global Cataracts Market

Global Wire and Cable Market

Global Plant-Based Food Market

Global Tomatoes Market

About Data Bridge Market Research:

An absolute way to forecast what the future holds is to comprehend the trend today!

Data Bridge Market Research set forth itself as an unconventional and neoteric market research and consulting firm with an unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process. Data Bridge is an aftermath of sheer wisdom and experience which was formulated and framed in the year 2015 in Pune.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Email:- corporatesales@databridgemarketresearch.com