The Mass Flow Controller Market Size is witnessing substantial growth due to rising demand for accurate flow measurement devices across various industrial sectors. Industrial mass flow devices, coriolis mass flow controllers, and precision flow regulators are increasingly being adopted for applications ranging from semiconductor manufacturing to bioreactors. Companies are focusing on enhancing mass flow rate controller accuracy and reliability to meet stringent process control standards, ensuring precise flow control in semiconductor market processes and other high-tech manufacturing environments.

Key Growth Drivers

The primary drivers for market growth include the increasing use of gas/liquid controllers and flow measurement devices in critical industrial applications. The adoption of advanced Capacitive Ceramic Pressure Sensor Market solutions is enhancing performance and precision of mass flow controllers, particularly in high-pressure and hazardous environments. Additionally, safety and compliance requirements are driving demand for reliable flow control equipment in industries such as chemicals, pharmaceuticals, and energy.

Rising industrial automation and the need for real-time monitoring of gas flowing and mass flow rates in production processes are further propelling market expansion. The growth of bioprocessing industries has increased the use of mass flow bioreactors and related precision flow control systems, ensuring consistent quality and yield. Moreover, integration with advanced digital control systems allows seamless operation and enhanced data accuracy for mass flow applications.

Regional Trends and Technological Influence

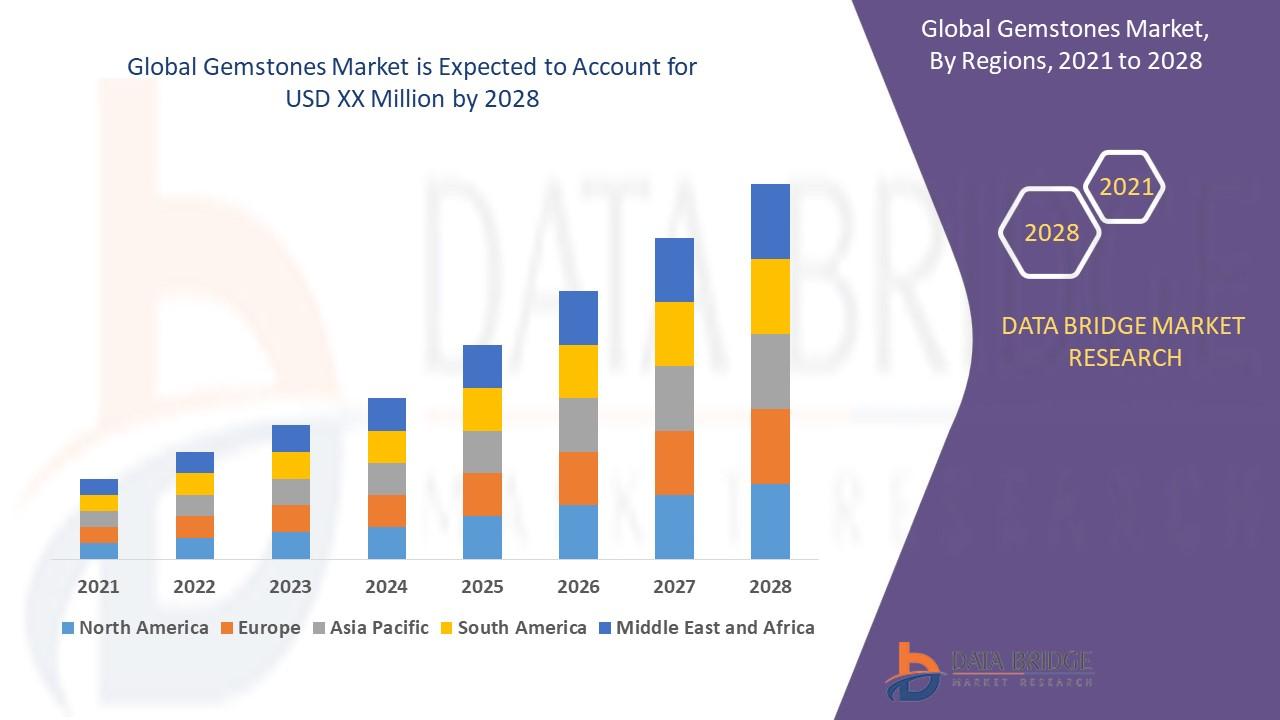

North America remains a key market, with high adoption of US Hazardous Area Equipment market solutions complementing mass flow controllers in environments requiring strict safety standards. Europe and Asia-Pacific are also witnessing rapid growth due to industrial expansion, technological adoption, and increasing semiconductor manufacturing activities. Digital integration and smart sensors in mass flow controllers are enabling predictive maintenance, reducing downtime, and optimizing operational efficiency.

Competitive Landscape and Future Outlook

Manufacturers are focusing on innovative solutions for precise mass flow rate controller applications, including coriolis mass flow controllers and industrial gas/liquid flow devices. Strategic collaborations, product enhancements, and technology integration are expected to drive market growth further. With rising industrialization, increasing automation, and stringent quality control requirements, the Mass Flow Controller Market is poised for steady expansion, catering to diverse sectors such as pharmaceuticals, semiconductors, chemicals, and energy.

FAQs

-

What applications use mass flow controllers?

Mass flow controllers are used in semiconductor manufacturing, bioreactors, chemical processing, and other industrial applications requiring precise flow measurement of gases or liquids. -

How do coriolis mass flow controllers differ from traditional flow regulators?

Coriolis mass flow controllers measure mass flow directly and provide higher accuracy, reliability, and precision compared to traditional volumetric or pressure-based flow regulators. -

Which regions are driving growth in the mass flow controller market?

North America, Europe, and Asia-Pacific are key growth regions due to industrial expansion, semiconductor manufacturing, and adoption of advanced flow measurement technologies.➤➤Explore Market Research Future – Related Insights

Asia Pacific Customer Touchpoint Evaluation System Market

Wafer Inspection System Market